Part

01

of one

Part

01

US & Canada Crop Spacing

American crop developers and universities suggest that while the crop spacing for commercial carrot production in the US does not vary by carrot variety, the intended carrot use / production method has a significant impact on spacing both within rows as well as between rows.

Carrot Crop Spacing in the US

Seminis

- US-based crop developer Seminis reports that "many different row/bed/spacing arrangements" are currently used in US commercial carrot production.

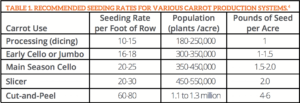

- As evidence of this, the crop developer provides a table for seeding rate standards by carrot use, as highlighted below.

- Specifically, Seminis reports that commercially produced carrots that are intended for dicing are spaced within rows at 6 to 12 seeds per foot, carrots intended for fresh market and slicer use are spaced within rows at 20 to 30 seeds per foot and cut-and-peel carrots are spaced at up to 60 to 80 seeds per foot.

- In parallel, the spacing between carrot rows also varies by carrot use, although the most "common method" at commercial farms is to plant twin-rows that are 2.5 to 3.5 inches apart, with each set of rows spaced at 14 to 18 inch intervals between one another.

- However, fresh market and processing growers may opt for single row planting with rows between 2 and 10 inches apart.

Rutgers University

- Rutgers University published a 2020/2021 guide for commercial carrot production in the US, where the school also differentiates spacing by carrot use / processing method.

- For processing carrots, rows are spaced 1836 inches apart, while in-row spacing varies for coins (16 plants per foot), dicing (6 plants per foot) and dicing in fine-textured soil (8 plants per foot).

- While fresh market and cut-and-peel carrots have rows that are also spaced 1836 inches apart, these production types have an in-row spacing of 6 to 8 plants per foot.

- Meanwhile, processing and fresh carrots have rows that are spaced 1.5 to 2 inches apart, while in-row spacing is 1.5 to 2 inches (or 4 to 6 seeds per foot) for dicers and 6 to 8 plants per foot for slicers/fresh carrots.

University of Georgia

- Meanwhile, American University, University of Georgia, also indicates that US commercial farms do not generally differentiate carrot crop spacing by carrot variety.

- Similar to Seminis, the university reports that commercial operations look to plant carrots in "twin rows" that are between 2.5 and 3.5 inches apart, adding that these sets of twin rows are most often placed 14 to 18 inches apart.

- Additionally, within each individual row, carrots are most typically spaced apart by 1.5 to 2 inches.

Cornell University

- Slightly dated (2016) information from Cornell University mirrors that of the University of Georgia, by suggesting that US commercial farms do not adjust carrot crop spacing by carrot variety.

- Specifically, the university reports that for the most common commercially produced carrot varieties (e.g., nantes, chantenay and danvers), in-row spacing is generally 1.5 inches, while between row spacing is 18 to 36 inches.

In contrast with the US, the Canadian provinces of Saskatchewan and British Columbia report that crop spacing for commercially produced carrots may vary significantly depending on both carrot variety and production type.

Carrot Crop Spacing in Canada

Government of Saskatchewan

- The government website for the Canadian Provence of Saskatchewan reports commercially produced carrots are typically planted at the rate of 10 to 16 plants per foot within rows for nantes carrot varieties.

- Notably, the government reports that a slightly different spacing of 12 to 18 plants per foot within rows is used for imperator carrot varieties.

- Meanwhile, between row spacing for carrots appears to be consistent across carrot varieties in the region (i.e., nantes, imperator, chantenay, danvers), and is typically between 16 to 30 inches.

Government of British Columbia

- In contrast, the government website for the Canadian Provence of British Columbia suggests that commercial farmers use different crop spacing based on production type (i.e., regular, cut-and-peel, baby-whole) rather than variety.

- For the more traditional production of carrots, the spacing between rows is typically 36 cm, however "some growers" are moving to 46 to 48 cm between rows.

- Additionally, in-row spacing for traditional carrot production is typically managed with a " special shoe," wherein 3 lines are seeded per row, with 6 to 7 seeds per 30 cm that are evenly spaced in a triangular pattern.

- For cut-and-peel production (i.e., long carrots that are later cut into thirds), the similar between row spacing is utilized, but in-row spacing is anywhere from twice to three times as dense.

- Finally, for baby-whole carrots, seeds are sown at "high density" within rows, and rows are spaced 22 to 30 cm apart.

American Universities report that commercial onion farms in the US vary crop spacing by onion type, with dry bulb onions spaced farther apart both within and between rows compared to sweet/Spanish onions or onion sets.

Onion Crop Spacing in the US

Penn State University

- According to American university, Penn State, commercial growers in the country "generally" plant 75,000 to 120,000 onions per acre in single rows, wherein onions are spaced by 2 inches within each row and onion rows are spaced 24 inches apart.

- Specifically for the production of large sweet or Spanish onions, commercial farms increase in-row spacing to 4 and 6 inches between plants.

- Additionally, Penn State's R&D unit, PlantVillage, provides more detailed descriptions for onion spacing for smaller-scale farms.

- Specifically, the resource notes that onion seeds and transplants generally allow 10 to 13 cm for in-row spacing and 30 to 45 cm (12 to 18 inches) between rows, while onion sets allow 5 to 7.5 cm for in-row spacing and 25 cm (10 inches) between rows.

Rutgers University

- Rutgers University published a 2020/2021 guide for commercial onion production in the US, where the school also differentiates between spacing for dry bulb onions, sweet Spanish onions and bunching onions.

- Similar to Penn State, Rutgers indicates that dry bulb onion rows are spaced 24 inches apart, but that onions are spaced slightly closer than 2 inches apart within rows (i.e., 8-9 onions per foot within rows).

- Additionally, Rutgers reports that sweet Spanish onion rows should be spaced a closer 4 to 5 inches apart, and that onions are spaced 1/2 to 2 inches apart within rows.

- Lastly, Rutgers suggests that bunching onion rows are spaced 12 to 16 inches apart, while seeds are spaced much more closely within rows at 1/2 to 1 1/2 inches apart.

University of Georgia

- The US school, University of Georgia, also provides details regarding commercial onion production in the US.

- Similar to Penn State and Rutgers University, the University of Georgia reports that onions are spaced between 4 and 6 inches apart between plants for commercial operations.

- However, the higher education institution adds that onions in the US may be planted with much more narrow spacing between rows (12 to 14 inches apart).

- Notably, the University of Georgia also does not indicate that different in-row or between row spacing is required for different commercial onion varieties in the US (e.g., sweet vidalia, candy ann, nirvana, honeybee).

The Canadian provinces of Saskatchewan and British Columbia report that crop spacing for onions is relatively consistent between rows, but that in-row spacing may vary significantly by onion type and planting technique.

Onion Crop Spacing in Canada

Government of Saskatchewan

- In a manner similar to the US, the government website for the Canadian Provence of Saskatchewan reports that crop spacing for commercial onions varies by onion type (i.e., dry, sets, bunching).

- Specifically, the government reports the within row spacing by seed density for dry onions ["2.2 to 2.9 kg/ha (2 to 2.5 lbs/acre)"], onion sets ["50 to 78 kg/ha (45 to 70 lbs/acre) "] and bunching onions ["11.2 to 27.9 kg/ha (10 to 25 lbs/ac)"].

- However, Saskatchewan suggests that spacing between rows is relatively independent of onion type, and is "normally" between 36 to 46 cm (14 to 18 inches).

Government of British Columbia

- In contrast, the government website for the Canadian Provence of British Columbia differentiates commercial onion spacing based on planting technique (i.e., transplants, direct seeded and precision seeded).

- For example, transplanted onions are spaced by 6 to 7.5 cm within rows and 40 cm between rows.

- In contrast, directly seeded spring onions are spaced within rows by 11 seeds per 25 cm, and between rows with 4 rows per 1.8 m centers.

- Finally, precision seeded onions are spaced by 7.5 cm within rows, and between rows with 4 rows per 1.8 m centers.

Although complete wheel spacing information for the most popular tillage/harvesting equipment in North America does not appear to be publicly available, equipment specifications from the top agricultural equipment manufacturers indicate that end-to-end wheel spacing varies dramatically across brands and their individual models.

Tillage & Harvester Wheel Spacing

Brand/Model Findings

- The research team conducted an extensive review of agriculture trade publications (e.g., Successful Farming), industry research (e.g., University of Nebraska) and reports by government agencies (e.g., US Department of Agriculture) to identify wheel spacing information for popular tillage and harvester equipment models.

- Notably, these resources provided only general and/or dated information regarding the impacts of wheel paths, wheel tracks and traffic lanes on crop spacing in the US and Canada.

- As a separate strategy, the research team reviewed the websites, brochures and other material published specifically by Deere & Company (e.g., website, brochure), CNH Industrial (e.g., website, brochure) and AGCO Corporation (e.g., website, brochure) to obtain the equipment specifications for their agricultural products.

- Deere & Company, CNH Industrial and AGCO Corporation were selected for this company-specific search given that they hold the largest market share in tractors and other agricultural machinery in the US, according to IBISWorld.

- During this process, the research team also identified a more comprehensive database of agricultural equipment specifications that includes a wider variety of brands sold in North America. A link to the equipment comparison tool hosted by CASE IH is available here.

- An exhaustive review of these brand and model-specific information sources was unable to identify any internal wheel spacing information (i.e., the spacing of wheels throughout the length of a piece of tillage/harvester equipment), however data related to wheel spacing on the extremities for these types of agricultural equipment was available.

- For example, the below screenshot reports the minimum and maximum working width for the CASE IH (CNH Industrial) Speed-Tiller High-Speed Disk (5 feet 9 inches to 18 feet), John Deere 2680 Three-Section Drawn (25 feet to 45 feet) and Sunflower (AGCO Corporation) 6830 NT Narrow-Transport (17 feet 8 inches to 21 feet 5 inches).

- Overall, a review of various brand/model configurations for agricultural equipment revealed that end-to-end wheel spacing for tillage and harvester equipment varies significantly.